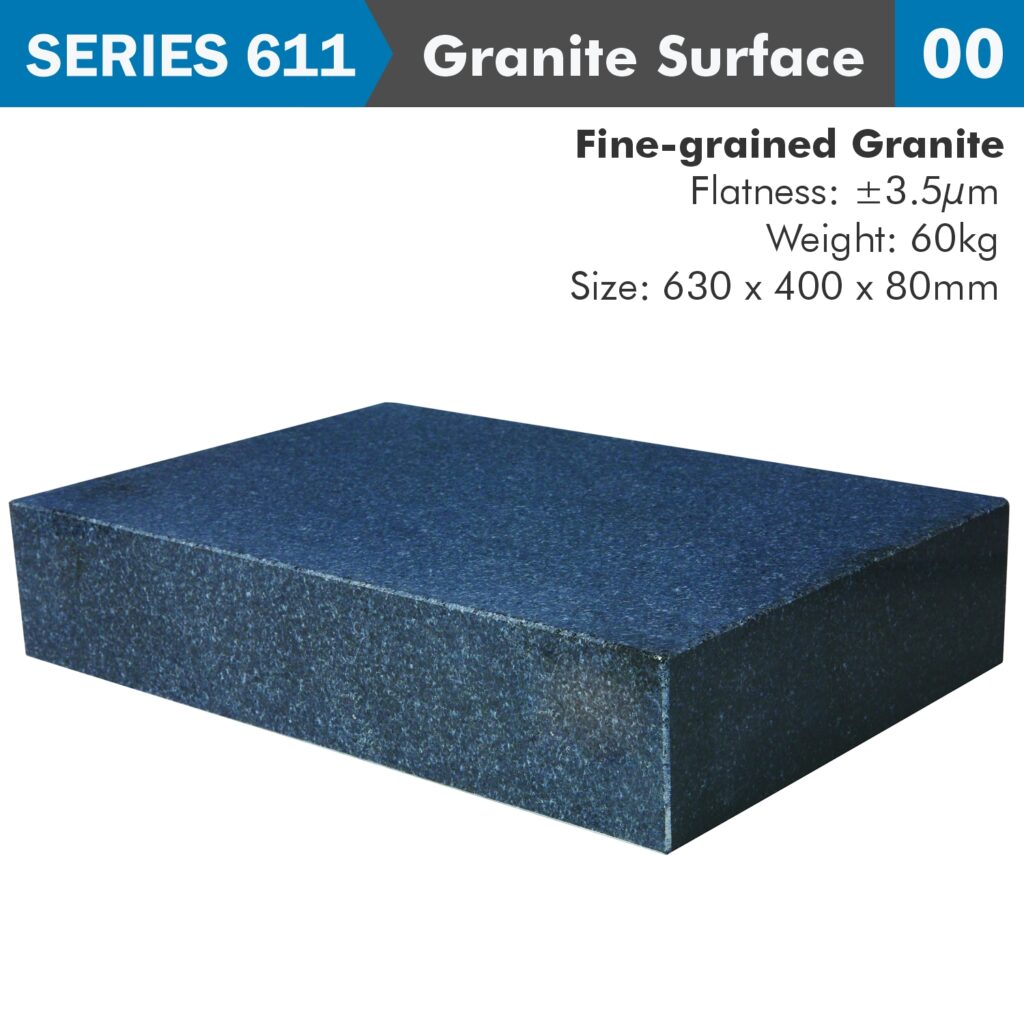

Granite Surface Plate – Laboratory Grade 00 – 630 x 400 x 80mm

SERIES 611

SERIES 611

A granite surface plate is a flat, stable reference surface made from high-quality,

precision-ground granite. It is primarily used in industrial and laboratory environments

for precise measurement and inspection tasks. The stability, durability, and wear

resistance of granite make it an ideal material for surface plates, particularly

for maintaining accuracy over time under heavy use.

Applications of a Granite Surface Plate:

-

Precision Inspection:

- Surface plates are used as a reference plane for inspecting parts for

flatness, squareness, parallelism,

and other geometrical dimensions. Instruments such as dial indicators,

height gauges, and CMM (Coordinate Measuring Machines)

are often used in conjunction with a surface plate to measure parts accurately.

- Surface plates are used as a reference plane for inspecting parts for

-

Layout Work:

- In manufacturing or machining, granite surface plates are used as the

base for marking out precise locations on a workpiece, especially for holes,

cutouts, or assembly points.

- In manufacturing or machining, granite surface plates are used as the

-

Calibration:

- Tools like micrometers, calipers,

and dial indicators are often calibrated against a granite

surface plate, ensuring that they are accurate when used for measurement.

- Tools like micrometers, calipers,

-

Precision Assembly:

- Surface plates serve as a platform for assembling precision components,

allowing for consistent alignment and the elimination of errors in fit or

dimension.

- Surface plates serve as a platform for assembling precision components,

-

CMM Base:

- In coordinate measuring machines (CMMs), granite is often used as the

base plate because of its dimensional stability, ensuring the CMM performs

consistently and accurately.

- In coordinate measuring machines (CMMs), granite is often used as the

Advantages of Using Granite Surface Plates:

-

Superior Flatness:

- Granite can be ground and lapped to an incredibly high degree of flatness,

offering a reference surface that remains consistent over time.

- Granite can be ground and lapped to an incredibly high degree of flatness,

-

Non-reactive:

- Granite does not rust, corrode, or react chemically with most materials,

making it ideal for use in various environments, including labs with sensitive

equipment.

- Granite does not rust, corrode, or react chemically with most materials,

-

Thermal Stability:

- Granite has a low coefficient of thermal expansion, meaning it doesn’t

expand or contract significantly with temperature changes, maintaining accuracy

across different environments.

- Granite has a low coefficient of thermal expansion, meaning it doesn’t

-

Long Lifespan:

- Due to its hardness and durability, granite surface plates last for

many years with minimal wear. They are much more resistant to scratches

and damage compared to steel plates.

- Due to its hardness and durability, granite surface plates last for

-

Vibration Dampening:

- Granite naturally absorbs vibrations, which helps ensure more accurate

measurements by minimizing disturbances when working with sensitive instruments.

- Granite naturally absorbs vibrations, which helps ensure more accurate